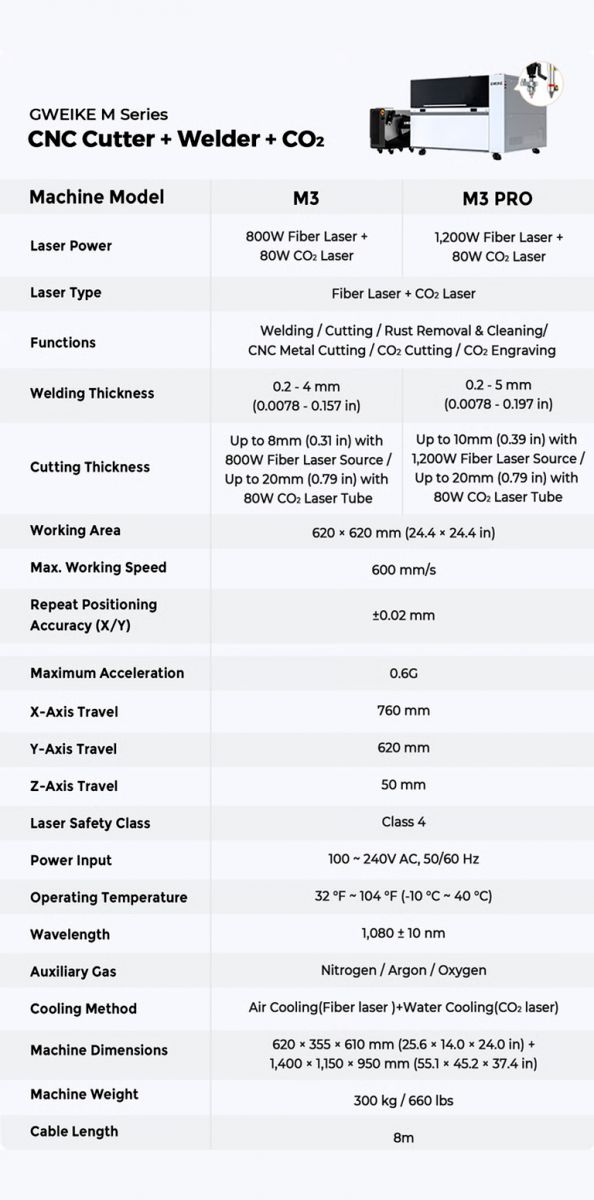

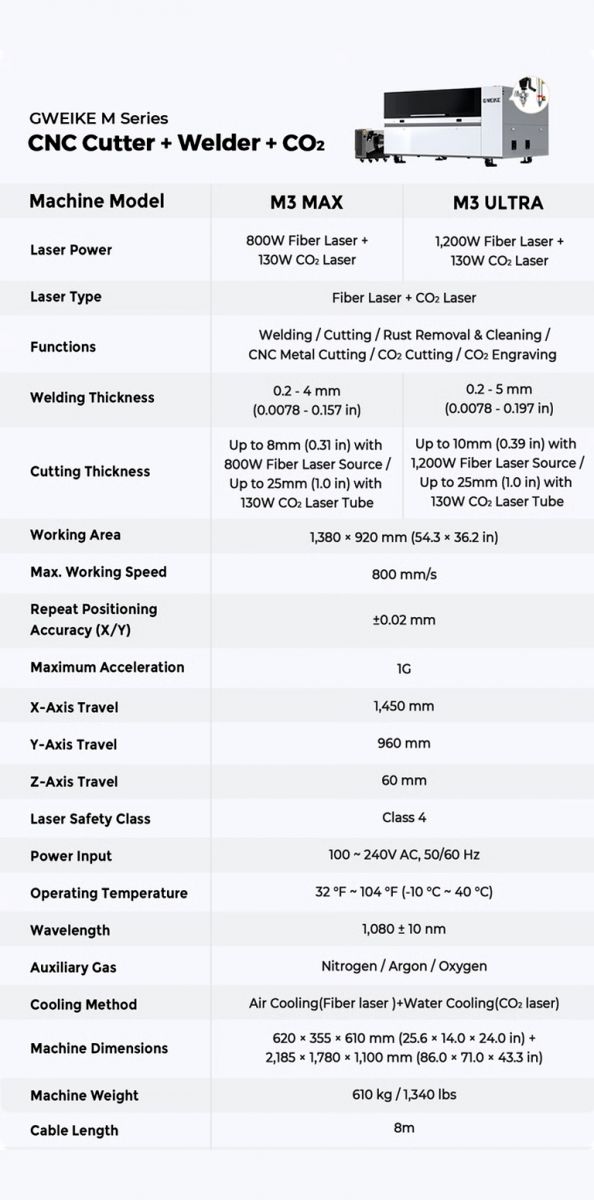

M Series The World's First 6-IN-1 Fiber Laser System | One Machine, Endless Possibilities

Catch the GWEIKE M Series Live Stream

.gif)

.gif)

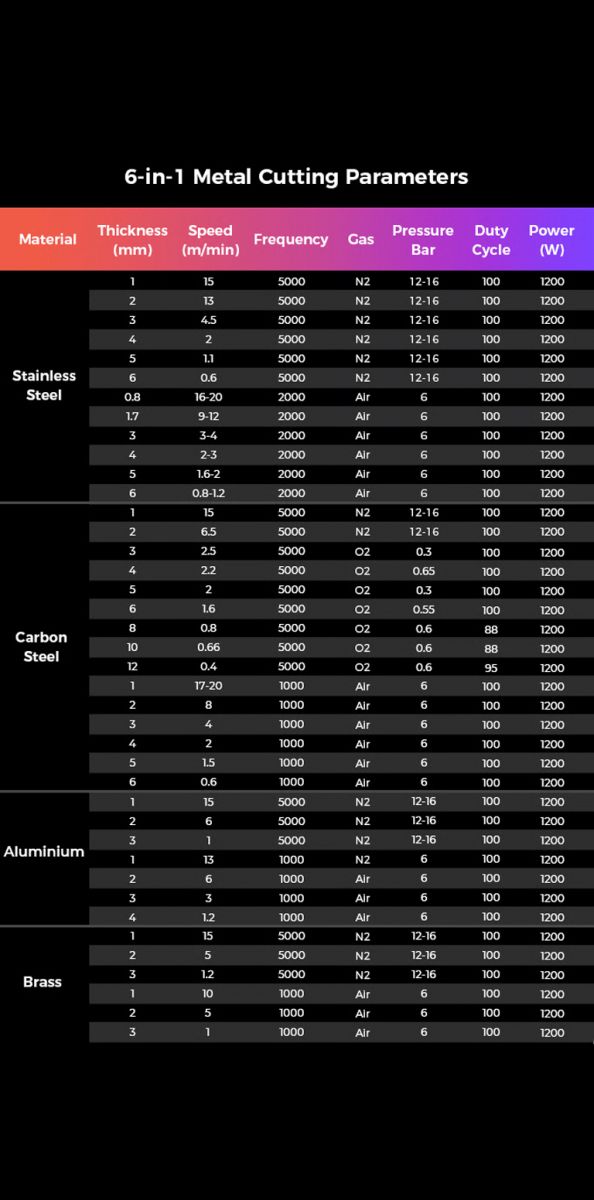

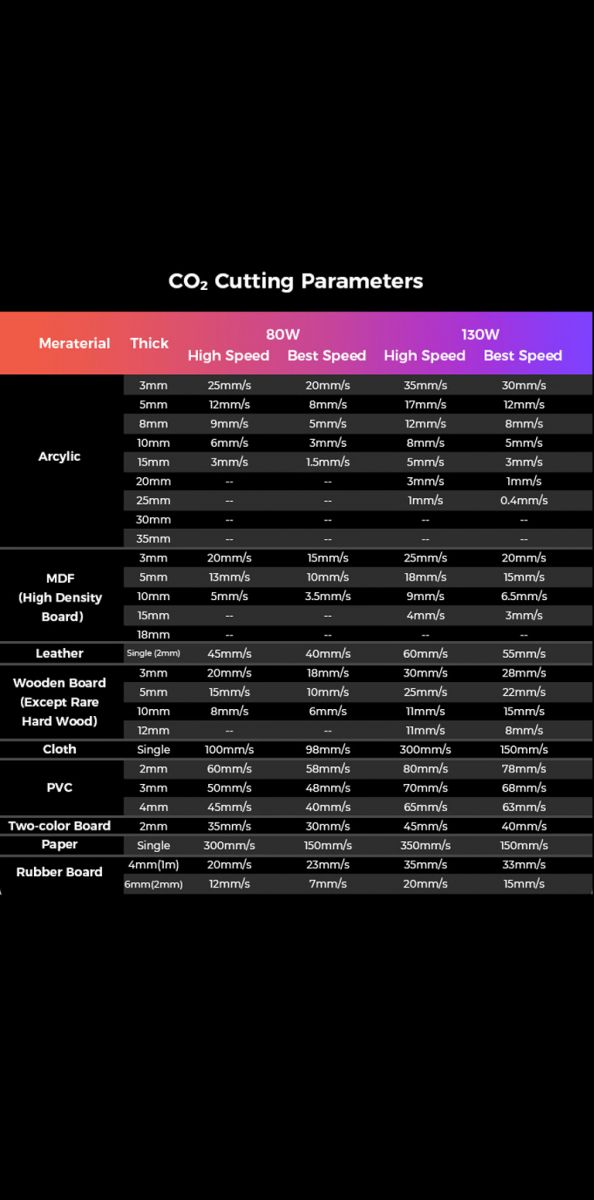

Deeper Cut, Stronger Act

.gif)

.gif)

Autonomous Obstacle Avoidance

When encountering obstacles, the path can be automatically adjusted to avoid collisions, thereby reducing production interruptions caused by manual intervention, improving production efficiency and ensuring production safety.

Industrial Nesting Software, Improves Material Utilization

Use efficient algorithms (such as automatic nesting, common edge cutting, and leftover material splicing) to maximize sheet material utilization, especially for special-shaped parts, which can save 15%~30% of raw materials.

Common Edge Cutting, Saves Materials And Time

Traditional independent cutting requires a reserved cutting margin (usually 0.2~0.5mm/edge), while common edge cutting eliminates redundant intervals by sharing a common cutting line, increasing material utilization by 10%~25% Shared edges only require one cut to separate adjacent parts, reducing the cutting stroke by 30%~50% compared to traditional methods

Traceless Micro-jointing Anti-deformation, High Precision

When cutting complex contours, by reserving micron-level tiny connection points (micro-connection points), the overall structure of the material is kept stable to avoid deformation or displacement of thin plates (such as 0.1~1mm) due to stress release during the cutting process.

Intelligent Flowing Cutting, Improves Production Efficiency

No-stop cutting, saving idle time, single positioning can complete the whole board cutting, greatly shortening the delivery cycle. The cutting head does not need to return to the origin after each processing, and can quickly jump and position on the board to achieve continuous cutting.

Automatic Edge Finder

The machine automatically detects the position of your material, making the process simple and intelligent.

Rotary Attachment

The rotary attachment enables 360° continuous rotation , expanding machining capabilities for cylindrical.

.jpg)

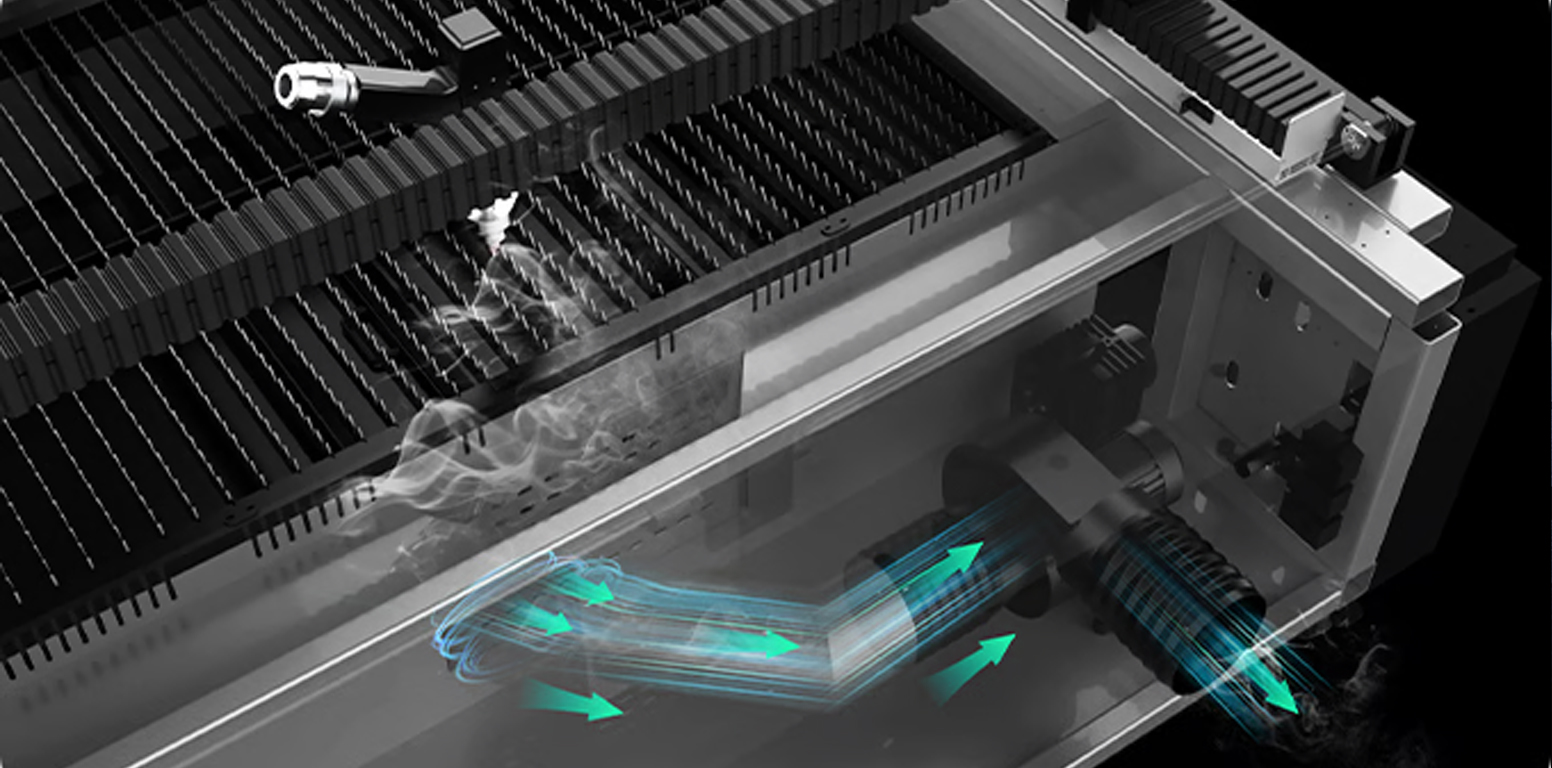

Traditional equipment (such as oxygen-fuel cutting) generates exhaust pollution. In contrast, fiber laser have low energy consumption (30-50% less electricity than CO₂ laser), and laser cleaning produces no wastewater, complying with environmental regulations (EPA standards).Equipped with an industrial-grade centrifugal fan which delivers strong suction power to quickly remove cutting smoke and exhaust. It operates stably and is suitable for long hours of continuous use.